-

Welcome to N.D. Sales Corporation

N.D. Sales is a trusted name in Bearing Trade. N.D. Sales Corporation Established in 1995 As A 100% supply Oriented Trading House of Bearing For various industries.

read more Engineering Units like Machinery , Tool room Ind., Pharma Machineries, Textile Machineries, Agro Machineries, Pumps, Diesel Engines And Gensets Along With Heavy Automobile Spare Parts. Offering a wide range of imported bearings, needle roller bearings, linear bearings, rod end bearings, spherical bearings, cylindrical bearings, clutch bearings, ball bearings, plain bearings, axial bearings, bearings for screw drivers, etc. Our Goal Was Clearly Defended As To Be A Leading Supplier For World Class Bearing With OEM Quality. Within A Span Of Few Years Of Hard Work, We Achieved Our Goal As Leading suppliers, With Quality Products Supplier In Domestic Market. We Have Our Own In House Sourcing And Quality Control Facility With World Class Equipments, Gauges And Instruments. Our Annual Turnover Graph Is Always On Constant Growth, Because Keeping Our Buyer Satisfied Is Always On Our Priority List. We sale not only bearing but we build a relation bridge with our clients. Recently We Have Decided to Enter In to International Market With Our Services And Products. With Our Past Experience And Detailed Knowledge Of Our Products. We Could Penetrate Into International Market Without Much Effort.

Engineering Units like Machinery , Tool room Ind., Pharma Machineries, Textile Machineries, Agro Machineries, Pumps, Diesel Engines And Gensets Along With Heavy Automobile Spare Parts. Offering a wide range of imported bearings, needle roller bearings, linear bearings, rod end bearings, spherical bearings, cylindrical bearings, clutch bearings, ball bearings, plain bearings, axial bearings, bearings for screw drivers, etc. Our Goal Was Clearly Defended As To Be A Leading Supplier For World Class Bearing With OEM Quality. Within A Span Of Few Years Of Hard Work, We Achieved Our Goal As Leading suppliers, With Quality Products Supplier In Domestic Market. We Have Our Own In House Sourcing And Quality Control Facility With World Class Equipments, Gauges And Instruments. Our Annual Turnover Graph Is Always On Constant Growth, Because Keeping Our Buyer Satisfied Is Always On Our Priority List. We sale not only bearing but we build a relation bridge with our clients. Recently We Have Decided to Enter In to International Market With Our Services And Products. With Our Past Experience And Detailed Knowledge Of Our Products. We Could Penetrate Into International Market Without Much Effort.

We Deal in

-

category

product overview

Ball Bearing

read moreTaper Roller Bearing

read moreRoller Bearing

read moreSpherical Bearing

read moreNeedle Bearing

read moreBall Screw

read moreBearing Shaft

read moreDouble Row Ball Bearing

read moreAngular Contact Bearing

read morePedestal Bearing

read moreRod End Bearing

read moreBall Thrust Bearing

read moreRoller Thrust Bearing

read more -

Ball Bearing

Ball bearings, as shown below, are probably the most common type of bearing. They are found in everything from inline skates to hard drives. These bearings can handle both radial and thrust loads, and are usually found in applications where the load is relatively small.

Ball bearings, as shown below, are probably the most common type of bearing. They are found in everything from inline skates to hard drives. These bearings can handle both radial and thrust loads, and are usually found in applications where the load is relatively small.

Cutaway view of a ball bearing

In a ball bearing, the load is transmitted from the outer race to the ball, and from the ball to the inner race. Since the ball is a sphere, it only contacts the inner and outer race at a very small point, which helps it spin very smoothly. But it also means that there is not very much contact area holding that load, so if the bearing is overloaded, the balls can deform or squish, ruining the bearing.

Cutaway view of a ball bearing

In a ball bearing, the load is transmitted from the outer race to the ball, and from the ball to the inner race. Since the ball is a sphere, it only contacts the inner and outer race at a very small point, which helps it spin very smoothly. But it also means that there is not very much contact area holding that load, so if the bearing is overloaded, the balls can deform or squish, ruining the bearing.

We Deal in

-

Tapper Roller Bearing

The inner and outer ring raceways are segments of cones and the rollers are also made with a taper so that the conical surfaces of the raceways and the roller axes if projected, would all meet at a common point on the main axis of the bearing.

This conical geometry is used as it gives a larger contact patch, which permits greater loads to be carried than with spherical (ball) bearings, while the geometry means that the tangential speeds of the surfaces of each of the rollers are the same as their raceways along the whole length of the contact patch and no differential scrubbing occurs. When a roller slides rather than rolls, it can generate wear at the roller-to-race interface, i.e. the differences in surface speeds creates a scrubbing action. Wear will degenerate the close tolerances normally held in the bearing and can lead to other problems. Much closer to pure rolling can be achieved in a tapered roller bearing and this avoids rapid wear.

The inner and outer ring raceways are segments of cones and the rollers are also made with a taper so that the conical surfaces of the raceways and the roller axes if projected, would all meet at a common point on the main axis of the bearing.

This conical geometry is used as it gives a larger contact patch, which permits greater loads to be carried than with spherical (ball) bearings, while the geometry means that the tangential speeds of the surfaces of each of the rollers are the same as their raceways along the whole length of the contact patch and no differential scrubbing occurs. When a roller slides rather than rolls, it can generate wear at the roller-to-race interface, i.e. the differences in surface speeds creates a scrubbing action. Wear will degenerate the close tolerances normally held in the bearing and can lead to other problems. Much closer to pure rolling can be achieved in a tapered roller bearing and this avoids rapid wear.

The rollers are guided by a flange on the inner ring. This stops the rollers from sliding out at high speed due to their momentum.

The larger the half angles of these cones the larger the axial force that the bearing can sustain.

The rollers are guided by a flange on the inner ring. This stops the rollers from sliding out at high speed due to their momentum.

The larger the half angles of these cones the larger the axial force that the bearing can sustain.

Tapered roller bearings are separable and have the following components: outer ring, inner ring, and roller assembly (containing the rollers and a cage). The non-separable inner ring and roller assembly is called the cone, and the outer ring is called the cup. Internal clearance is established during mounting by the axial position of the cone relative to the cup.

History

In 1898, Henry Timken was awarded a patent[1] for the tapered roller bearing. At the time, Timken was a carriage-maker in St. Louis and held three patents for carriage springs. However, it was his patent for tapered roller bearings that allowed his company to become successful.

In 1898, Henry Timken was awarded a patent[1] for the tapered roller bearing. At the time, Timken was a carriage-maker in St. Louis and held three patents for carriage springs. However, it was his patent for tapered roller bearings that allowed his company to become successful.

Tapered roller bearings were a breakthrough at the end of the 19th century because bearings used in wheel axles had not changed much since ancient times. They relied on bearings enclosed in a case that held lubricants. These were called journal bearings and depended on lubricants to function. Without proper lubrication, these bearings would fail due to excessive heat caused by friction. Timken was able to significantly reduce the friction on his bearings by using a cup and cone design incorporating tapered bearings which actually rolled, which reduced the load placed on the bearings by distributing the weight and load evenly across the cups, cones, and bearings.

Applications

In many applications tapered roller bearings are used in back-to-back pairs so that axial forces can be supported equally in either direction.

Pairs of tapered roller bearings are used in car and vehicle wheel bearings where they must cope simultaneously with large vertical (radial) and horizontal (axial) forces

We Deal in

-

Roller Bearing

roller bearing, one of the two members of the class of rolling, or so-called antifriction, bearings (the other member of the class is the ball bearing . Like a ball bearing, a roller bearing has two grooved tracks, or races, but the balls are replaced by rollers. The rollers may be cylinders or truncated cones. Only radial loads (i.e., loads perpendicular to the axis of rotation) can be carried when the rollers are cylindrical, but with conical rollers both radial and thrust, or axial, loads (i.e., ones parallel to the axis of rotation) can be carried. A needle bearing has cylindrical rollers that are relatively slender and completely fill the space between the races; in many cases the inner race is dispensed with. Because there is line contact between a roller and the races, while in a ball bearing there is point contact, in a given space a roller bearing can carry a greater radial load than a ball bearing.

roller bearing, one of the two members of the class of rolling, or so-called antifriction, bearings (the other member of the class is the ball bearing . Like a ball bearing, a roller bearing has two grooved tracks, or races, but the balls are replaced by rollers. The rollers may be cylinders or truncated cones. Only radial loads (i.e., loads perpendicular to the axis of rotation) can be carried when the rollers are cylindrical, but with conical rollers both radial and thrust, or axial, loads (i.e., ones parallel to the axis of rotation) can be carried. A needle bearing has cylindrical rollers that are relatively slender and completely fill the space between the races; in many cases the inner race is dispensed with. Because there is line contact between a roller and the races, while in a ball bearing there is point contact, in a given space a roller bearing can carry a greater radial load than a ball bearing.

We Deal in

-

Spherical Bearing

A spherical bearing is a bearing that permits angular rotation about a central point in two orthogonal directions (usually within a specified angular limit based on the bearing geometry). Typically these bearings support a rotating shaft in the [bore] of the inner ring that must move not only rotationally, but also at an angle.

A spherical bearing is a bearing that permits angular rotation about a central point in two orthogonal directions (usually within a specified angular limit based on the bearing geometry). Typically these bearings support a rotating shaft in the [bore] of the inner ring that must move not only rotationally, but also at an angle.

Construction

Construction of spherical bearings can be hydrostatic or strictly mechanical. A spherical bearing by itself can consist of an outer ring and an inner ring and a locking feature that makes the inner ring captive within the outer ring in the axial direction only. The outer surface of the inner ring and the inner surface of the outer ring are collectively considered the raceway and they slide against each other, either with a lubricant or a maintenance-free polytetrafluoroethylene (PTFE) based liner. Some spherical bearings incorporate a rolling element such as a race of ball-bearings, allowing lower friction.

History

The Swede Sven Wingquist (1876–1953) invented the spherical bearing in 1907. He founded a global company, AB Svenska Kullagerfabriken, still the world’s leading producer of industrial bearings.

Application

Spherical bearings are used in countless applications, wherever rotational motion must be allowed to change the alignment of its rotation axis. A prime example is a tie rod on a vehicle suspension. The mechanics of the suspension allow the axle to move up and down, but the linkages are designed to control that motion in one direction only and they must allow motion in the other directions. Spherical bearings have been used in car suspensions, driveshafts, heavy machinery, sewing machines, and many other applications.We Deal in

-

Needle Bearing

A needle roller bearing is a bearing which uses small cylindrical rollers. They are used to reduce friction of a rotating surface.

Needle bearings have a large surface area that is in contact with the bearing outer surfaces compared to ball bearings. Additionally there is less added clearance (difference between the diameter of the shaft and the diameter of the bearing) so they are much more compact. The typical structure consists of an inner race (or sometimes merely a shaft), a needle cage which orients and contains the needle rollers, the needle rollers themselves, and an outer race.

A needle roller bearing is a bearing which uses small cylindrical rollers. They are used to reduce friction of a rotating surface.

Needle bearings have a large surface area that is in contact with the bearing outer surfaces compared to ball bearings. Additionally there is less added clearance (difference between the diameter of the shaft and the diameter of the bearing) so they are much more compact. The typical structure consists of an inner race (or sometimes merely a shaft), a needle cage which orients and contains the needle rollers, the needle rollers themselves, and an outer race.

Radial needle bearings are cylindrical and use rollers parallel to the axis of the shaft. Thrust needle bearings are flat and use a radial pattern of needles.

Needle bearings are heavily used in engine components such as rocker arm pivots, pumps, compressors, and transmissions. The drive shaft of a rear-wheel drive vehicle typically has at least 8 needle bearings (4 in each U joint) and often more if it is particularly long, or operates on steep slopes.

Additional clarification of Needle Roller: According to "Marks' Standard Handbook for Mechanical Engineers", a Needle Bearing is a roller bearing with rollers whose length are at least four times their diameter.

We Deal in

-

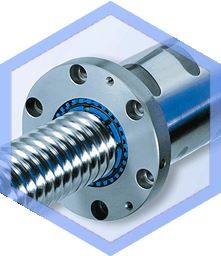

Ball Screw

A ball screw is a mechanical linear actuator that translates rotational motion to linear motion with little friction. A threaded shaft provides a spiral raceway for ball bearings which act as a precision screw. As well as being able to apply or withstand high thrust loads they can do so with minimum internal friction. They are made to close tolerances and are therefore suitable for use in situations in which high precision is necessary. The ball assembly acts as the nut while the threaded shaft is the screw.Photo showing two ball screws. Inset images are close-up photos of the ball assembly of the top screw. Left inset: recirculating tube removed showing retainer bracket, loose balls and tube. Right inset: closer view of the nut cavity.Ball screws are used in aircraft and missiles to move control surfaces, especially for electric fly by wire. They are also used in machine tools, robots and precision assembly equipment. High precision ball screws are used in steppers for semiconductor manufacturing.In contrast to conventional leadscrews, ballscrews tend to be rather bulky, due to the need to have a mechanism to re-circulate the balls.

A ball screw is a mechanical linear actuator that translates rotational motion to linear motion with little friction. A threaded shaft provides a spiral raceway for ball bearings which act as a precision screw. As well as being able to apply or withstand high thrust loads they can do so with minimum internal friction. They are made to close tolerances and are therefore suitable for use in situations in which high precision is necessary. The ball assembly acts as the nut while the threaded shaft is the screw.Photo showing two ball screws. Inset images are close-up photos of the ball assembly of the top screw. Left inset: recirculating tube removed showing retainer bracket, loose balls and tube. Right inset: closer view of the nut cavity.Ball screws are used in aircraft and missiles to move control surfaces, especially for electric fly by wire. They are also used in machine tools, robots and precision assembly equipment. High precision ball screws are used in steppers for semiconductor manufacturing.In contrast to conventional leadscrews, ballscrews tend to be rather bulky, due to the need to have a mechanism to re-circulate the balls.

To maintain their inherent accuracy and ensure long life, great care is needed to avoid contamination with dirt and abrasive particles. This may be achieved by using rubber or leather bellows to completely or partially enclose the working surfaces. Another solution is to use a positive pressure of filtered air when they are used in a semi-sealed or open enclosure. While reducing friction, ball screws can operate with some preload, effectively eliminating backlash (slop) between input (rotation) and output (linear motion). This feature is essential when they are used in computer-controlled motion-control systems, e.g. CNC machine tools and high precision motion applications (e.g. wire bonding).

Depending upon their lead angle, ball screws can be back-driven due to their low internal friction (i.e. the screw shaft can be driven linearly to rotate the ball nut). They are usually undesirable for hand-fed machine tools, as the stiffness of a servo motor is required to keep the cutter from grabbing the work and self feeding, that is, where the cutter and workpiece exceed the optimum feedrate and effectively jam or crash together, ruining the cutter and workpiece. Cost is also a major factor as Acme screws are cheaper to manufacture.

Low friction in ball screws yields high mechanical efficiency compared to alternatives. A typical ball screw may be 90 percent efficient, versus 50 percent efficiency of an Acme lead screw of equal size. The higher cost of ball screws may thus be offset by lower power requirements for the same net performance.

Ball screw shafts may be fabricated by rolling, yielding a less precise, but inexpensive and mechanically efficient product. Rolled ball screws have a positional precision of several thousandths of an inch per foot.

High-precision screw shafts are typically precise to one thousandth of an inch per foot or better. They have historically been machined to gross shape, case hardened and then ground. The three step process is needed because high temperature machining distorts the work-piece.[1] Hard whirling is a recent (2008) precision machining technique that minimizes heating of the work, and can produce precision screws from case-hardened bar stock.

Instrument quality screw shafts are typically precise to 250 nanometers per centimeter. They are produced on precision milling machines with optical distance measuring equipment and special tooling. Similar machines are used to produce optical lenses and mirrors. Instrument screw shafts are generally made of Invar, to prevent temperature from changing tolerances too much.

Historically, the first precise screwshafts were produced by starting with a low precision screwshaft, and then lapping the shaft with several spring-loaded nut laps. By rearranging and inverting the nut laps, the lengthwise errors of the nuts and shaft were averaged. Then, the very repeatable shaft's pitch is measured against a distance standard. A similar process is sometimes used today to produce reference standard screw shafts, or master manufacturing screw shafts.

We Deal in

-

Double Row Ball Bearing

A type of roller-element bearing consisting of a double-row of rolling elements. Bearings with a double row accept a greater amount of load than single-row designs. In some cases, a double-row design makes it possible for load to be carried in two directions.

A type of roller-element bearing consisting of a double-row of rolling elements. Bearings with a double row accept a greater amount of load than single-row designs. In some cases, a double-row design makes it possible for load to be carried in two directions.

We Deal in

-

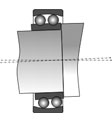

Angular Contact Bearing

An angular contact ball bearing uses axially asymmetric races. An axial load passes in a straight line through the bearing, whereas a radial load takes an oblique path that tends to want to separate the races axially. So the angle of contact on the inner race is the same as that on the outer race. Angular contact bearings better support "combined loads" (loading in both the radial and axial directions) and the contact angle of the bearing should be matched to the relative proportions of each. The larger the contact angle (typically in the range 10 to 45 degrees), the higher the axial load supported, but the lower the radial load. In high speed applications, such as turbines, jet engines, and dentistry equipment, the centrifugal forces generated by the balls changes the contact angle at the inner and outer race. Ceramics such as silicon nitride are now regularly used in such applications due to their low density (40% of steel). These materials significantly reduce centrifugal force and function well in high temperature environments. They also tend to wear similarly way to bearing steel—rather than cracking or shattering like glass or porcelain.

An angular contact ball bearing uses axially asymmetric races. An axial load passes in a straight line through the bearing, whereas a radial load takes an oblique path that tends to want to separate the races axially. So the angle of contact on the inner race is the same as that on the outer race. Angular contact bearings better support "combined loads" (loading in both the radial and axial directions) and the contact angle of the bearing should be matched to the relative proportions of each. The larger the contact angle (typically in the range 10 to 45 degrees), the higher the axial load supported, but the lower the radial load. In high speed applications, such as turbines, jet engines, and dentistry equipment, the centrifugal forces generated by the balls changes the contact angle at the inner and outer race. Ceramics such as silicon nitride are now regularly used in such applications due to their low density (40% of steel). These materials significantly reduce centrifugal force and function well in high temperature environments. They also tend to wear similarly way to bearing steel—rather than cracking or shattering like glass or porcelain.

Most bicycles use angular-contact bearings in the headsets because the forces on these bearings are in both the radial and axial direction.We Deal in

-

Pedestal Bearing

Pedestal bearing or Plummer block

Pedestal bearing or Plummer block

It is a split type of bearing. This type of bearing is used for higher speeds, heavy loads and large sizes.

The component of the bearing:

Cast iron pedestal or block with a sole

Brass or gun-metal or phosphorus-bronze “Brasses”, bushes or steps made in two halves.

Cast iron cap.

Two mild steel bolts and nuts.

Care is taken that the brasses do not move axially nor are allowed to rotate. For preventing this rotation , usually a snug at the bottom fitting inside a recess at the bottom of the pedestal is provided.

This bearing facilitates the placements and removal of the of the shaft from the bearing. Unlike the solid bearing which are to be inserted end-wise and hence are kept near the ends of the shaft, these can be placed anywhere. This bearing ensures a perfect adjustment for wear in the brasses by screwing the cap.We Deal in

-

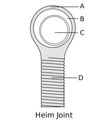

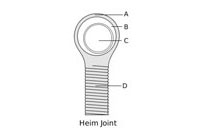

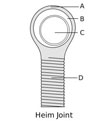

Rod End Bearing

A rod end bearing, also known as a heim joint (N. America) or rose joint (U.K. and elsewhere), is a mechanical articulating joint. Such joints are used on the ends of control rods, steering links, tie rods, or anywhere a precision articulating joint is required. A ball swivel with an opening through which a bolt or other attaching hardware may pass is pressed into a circular casing with a threaded shaft attached. The threaded portion may be either male or female.

A rod end bearing, also known as a heim joint (N. America) or rose joint (U.K. and elsewhere), is a mechanical articulating joint. Such joints are used on the ends of control rods, steering links, tie rods, or anywhere a precision articulating joint is required. A ball swivel with an opening through which a bolt or other attaching hardware may pass is pressed into a circular casing with a threaded shaft attached. The threaded portion may be either male or female.

History

The spherical rod end bearing was developed by the Germans in World War II.[1] When one of the first German planes to be shot down by the British in early 1940 was examined, they found this joint in use in the aircraft's control systems. The H.G. Heim Company was given an exclusive patent to manufacture these joints in North America, while in the UK the patent passed to Rose Bearings Ltd.[2] The ubiquity of these manufacturers in their respective markets led to the terms heim joint and rose joint becoming synonymous with their product. After the patents ran out, the common names stuck although "rose joint" remains a registered trademark of Rose Bearings Ltd. Originally used in aircraft, the rod end bearing may be found in cars, trucks, race cars, lawn tractors, boats, industrial machines, go-karts, radio-control helicopters, and many more applications.We Deal in

-

Ball Thrust Bearing

A thrust bearing is a particular type of rotary bearing. Like other rotary bearings they permit rotation between parts, but they are designed to support a high axial load while doing this.

A thrust bearing is a particular type of rotary bearing. Like other rotary bearings they permit rotation between parts, but they are designed to support a high axial load while doing this.

Thrust bearings come in several varieties.

Ball thrust bearings, composed of ball bearings supported in a ring, can be used in low thrust applications where there is little radial load. Are mostly used for low-speed applications and cannot handle much radial load. Barstools and Lazy Susan turntables use this type of bearing.

We Deal in

-

Roller Thrust Bearing

Roller thrust bearings consist of small cylindrical rollers arranged flat with their axes pointing to the axis of the bearing. They give very good carrying capacity and are cheap, but tend to wear due to the differences in radial speed and friction is higher than with ball bearings.

Roller thrust bearings consist of small cylindrical rollers arranged flat with their axes pointing to the axis of the bearing. They give very good carrying capacity and are cheap, but tend to wear due to the differences in radial speed and friction is higher than with ball bearings.

Can support large thrust loads. They are often found in gearsets like car transmissions between gears, and between the housing and the rotating shafts. The helical gears used in most transmissions have angled teeth -- this causes a thrust load that must be supported by a bearing.We Deal in

-

a little About Us

We have pleasure to introduce our self as one of the leading Stockist of all kind of Bearings

N.D. Sales Corporation is the Authorised Dealr for some of world most renouned Bearing Brands. Major turnover is by SKF, URB-ROMNIA & ZKL-Czechoslovakia, and other priority are FAG, NTN, RHP, KHK, FYH. N.D. Sales Corporation is a proven market leader in the supply of world - class bearings in the country. More than 2,000 customers rely on N.D. Sales Corporation. for their superior Technical Support Team, Best Price, Shortest Delivery Time the largest in the Western INDIA with an astonishing capability to supply more than 1,50,000 types of bearings from the world's leading bearing manufacturers. In keeping with our ever expanding enterprise, we have moved on from the times when we managed with a solitary office in Ahmedabad.

Our phenomenal success is linked to the ability to deliver any type of bearing anywhere within a short period of time. With clear focus on Total Dedication, Total Commitment and Total Quality.

N.D. Sales Corporation has an impressive track record of customer satisfaction, enabling it to retain its position as a preferred bearing supplier for industries both big and small.We Deal in

-

how to be our partners

Lorem ipsum dolor sit amet conse ctetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna.

Ipsum dolor sit amet conse ctetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat consectetuer adipiscing elit. Nunc suscipit. Suspendisse enim arcu, convallis non, cursus sed, dignissim et, est. Aenean semper aliquet libero.In ante velit, cursus ut, ultrices vitae, tempor ut, risus. Duis pulvinar. Vestibulum vel pede at sapien sodales mattis. Quisque pretium, lacus nec iacu

read moreOur partners

Lorem ipu dolr

Lorem ipu dolr

Lorem ipu dolr

Lorem ipu dolr

Lorem ipu dolr

Lorem ipu dolr

Lorem ipu dolr

Lorem ipu dolr

-

Qality And Brands

best service

Our Qyality Commitment

Quality if first factor that a consumar refar most. "NDSC" know requirements and supply best in the quality. No compromise what so have place in our work. We do not have ISO certification but we always try to supply Higher quality Than ISO... With Quality we also spot our aim on prompt and timely delivery factor. which have equl importance as quality. In sort NDSC confirms best for - QQQ ( Quality - Quantity - Quickly )

We Deal in

-

contact address

112, Astlaxmi complex , Telephone: +91-79-22138864

112, Astlaxmi complex , Telephone: +91-79-22138864

Outside Dariyapur Darwaja, Mob: +91 9925359359

Idgah Police Chowki Road, E-mail: sales@ndbearing.co.in

Dariyapur, Ahmedabad-380001.contact form

-

Privacy Policy

Quisque in lacus. Pellentesque vitae enim quis ante hendrerit lobortis. Nunc sit amet felis. Sed dui felis, vestibulum non, fringilla sed, elementum sit amet, sapien.

Nulla pharetra dignissim enim. Nam cursus eros ut massa. Proin rutrum. Donec non urna non leo aliquam cursus. Vivamus ornare viverra lacus. Fusce id sapien. Donec rhoncus, enim sit amet sodales elementum, elit odio sagittis erat, at tincidunt leo neque non pede. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos hymenaeos. Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Mauris ac leo. Aliquam magna nibh, tincidunt ut, lobortis feugiat, consectetuer sed, sapien. Aenean dui eros, tempus non, pulvinar in, vestibulum sed, urna. Nullam eget arcu a pede adipiscing vestibulum. Donec accumsan lacus nec dolor. Etiam porttitor elit. Quisque suscipit, arcu id porttitor vehicula, sem eros congue nulla, id consequat massa diam at dui. Quisque quis massa. Suspendisse metus justo, pellentesque et, sagittis sit amet, consectetuer imperdiet, sapien. Nullam eu neque eget risus porttitor accumsan. Vivamus cursus pretium tortor.

Nulla pharetra dignissim enim. Nam cursus eros ut massa. Proin rutrum. Donec non urna non leo aliquam cursus. Vivamus ornare viverra lacus. Fusce id sapien. Donec rhoncus, enim sit amet sodales elementum, elit odio sagittis erat, at tincidunt leo neque non pede. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos hymenaeos. Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Mauris ac leo. Aliquam magna nibh, tincidunt ut, lobortis feugiat, consectetuer sed, sapien. Aenean dui eros, tempus non, pulvinar in, vestibulum sed, urna. Nullam eget arcu a pede adipiscing vestibulum. Donec accumsan lacus nec dolor. Etiam porttitor elit. Quisque suscipit, arcu id porttitor vehicula, sem eros congue nulla, id consequat massa diam at dui. Quisque quis massa. Suspendisse metus justo, pellentesque et, sagittis sit amet, consectetuer imperdiet, sapien. Nullam eu neque eget risus porttitor accumsan. Vivamus cursus pretium tortor.

Nulla pharetra dignissim enim. Nam cursus eros ut massa. Proin rutrum. Donec non urna non leo aliquam cursus. Vivamus ornare viverra lacus. Fusce id sapien. Donec rhoncus, enim sit amet sodales elementum, elit odio sagittis erat, at tincidunt leo neque non pede. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos hymenaeos. Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Mauris ac leo. Aliquam magna nibh, tincidunt ut, lobortis feugiat, consectetuer sed, sapien. Aenean dui eros, tempus non, pulvinar in, vestibulum sed, urna. Nullam eget arcu a pede adipiscing vestibulum. Donec accumsan lacus nec dolor. Etiam porttitor elit. Quisque suscipit, arcu id porttitor vehicula, sem eros congue nulla, id consequat massa diam at dui. Quisque quis massa. Suspendisse metus justo, pellentesque et, sagittis sit amet, consectetuer imperdiet, sapien. Nullam eu neque eget risus porttitor accumsan. Vivamus cursus pretium tortor.

Nulla pharetra dignissim enim. Nam cursus eros ut massa. Proin rutrum. Donec non urna non leo aliquam cursus. Vivamus ornare viverra lacus. Fusce id sapien. Donec rhoncus, enim sit amet sodales elementum, elit odio sagittis erat, at tincidunt leo neque non pede. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos hymenaeos. Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Mauris ac leo. Aliquam magna nibh, tincidunt ut, lobortis feugiat, consectetuer sed, sapien. Aenean dui eros, tempus non, pulvinar in, vestibulum sed, urna. Nullam eget arcu a pede adipiscing vestibulum. Donec accumsan lacus nec dolor. Etiam porttitor elit. Quisque suscipit, arcu id porttitor vehicula, sem eros congue nulla, id consequat massa diam at dui. Quisque quis massa. Suspendisse metus justo, pellentesque et, sagittis sit amet, consectetuer imperdiet, sapien. Nullam eu neque eget risus porttitor accumsan. Vivamus cursus pretium tortor.

Nulla pharetra dignissim enim. Nam cursus eros ut massa. Proin rutrum. Donec non urna non leo aliquam cursus. Vivamus ornare viverra lacus. Fusce id sapien. Donec rhoncus, enim sit amet sodales elementum, elit odio sagittis erat, at tincidunt leo neque non pede. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos hymenaeos. Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Mauris ac leo. Aliquam magna nibh, tincidunt ut, lobortis feugiat, consectetuer sed, sapien. Aenean dui eros, tempus non, pulvinar in, vestibulum sed, urna. Nullam eget arcu a pede adipiscing vestibulum. Donec accumsan lacus nec dolor. Etiam porttitor elit. Quisque suscipit, arcu id porttitor vehicula, sem eros congue nulla, id consequat massa diam at dui. Quisque quis massa. Suspendisse metus justo, pellentesque et, sagittis sit amet, consectetuer imperdiet, sapien. Nullam eu neque eget risus porttitor accumsan. Vivamus cursus pretium tortor.

-

More

Quisque in lacus. Pellentesque vitae enim quis ante hendrerit lobortis. Nunc sit amet felis. Sed dui felis, vestibulum non, fringilla sed, elementum sit amet, sapien.

Nulla pharetra dignissim enim. Nam cursus eros ut massa. Proin rutrum. Donec non urna non leo aliquam cursus. Vivamus ornare viverra lacus. Fusce id sapien. Donec rhoncus, enim sit amet sodales elementum, elit odio sagittis erat, at tincidunt leo neque non pede. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos hymenaeos. Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Mauris ac leo. Aliquam magna nibh, tincidunt ut, lobortis feugiat, consectetuer sed, sapien. Aenean dui eros, tempus non, pulvinar in, vestibulum sed, urna. Nullam eget arcu a pede adipiscing vestibulum. Donec accumsan lacus nec dolor. Etiam porttitor elit. Quisque suscipit, arcu id porttitor vehicula, sem eros congue nulla, id consequat massa diam at dui. Quisque quis massa. Suspendisse metus justo, pellentesque et, sagittis sit amet, consectetuer imperdiet, sapien. Nullam eu neque eget risus porttitor accumsan. Vivamus cursus pretium tortor.

Nulla pharetra dignissim enim. Nam cursus eros ut massa. Proin rutrum. Donec non urna non leo aliquam cursus. Vivamus ornare viverra lacus. Fusce id sapien. Donec rhoncus, enim sit amet sodales elementum, elit odio sagittis erat, at tincidunt leo neque non pede. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos hymenaeos. Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Mauris ac leo. Aliquam magna nibh, tincidunt ut, lobortis feugiat, consectetuer sed, sapien. Aenean dui eros, tempus non, pulvinar in, vestibulum sed, urna. Nullam eget arcu a pede adipiscing vestibulum. Donec accumsan lacus nec dolor. Etiam porttitor elit. Quisque suscipit, arcu id porttitor vehicula, sem eros congue nulla, id consequat massa diam at dui. Quisque quis massa. Suspendisse metus justo, pellentesque et, sagittis sit amet, consectetuer imperdiet, sapien. Nullam eu neque eget risus porttitor accumsan. Vivamus cursus pretium tortor.

Nulla pharetra dignissim enim. Nam cursus eros ut massa. Proin rutrum. Donec non urna non leo aliquam cursus. Vivamus ornare viverra lacus. Fusce id sapien. Donec rhoncus, enim sit amet sodales elementum, elit odio sagittis erat, at tincidunt leo neque non pede. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos hymenaeos. Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Mauris ac leo. Aliquam magna nibh, tincidunt ut, lobortis feugiat, consectetuer sed, sapien. Aenean dui eros, tempus non, pulvinar in, vestibulum sed, urna. Nullam eget arcu a pede adipiscing vestibulum. Donec accumsan lacus nec dolor. Etiam porttitor elit. Quisque suscipit, arcu id porttitor vehicula, sem eros congue nulla, id consequat massa diam at dui. Quisque quis massa. Suspendisse metus justo, pellentesque et, sagittis sit amet, consectetuer imperdiet, sapien. Nullam eu neque eget risus porttitor accumsan. Vivamus cursus pretium tortor.

Nulla pharetra dignissim enim. Nam cursus eros ut massa. Proin rutrum. Donec non urna non leo aliquam cursus. Vivamus ornare viverra lacus. Fusce id sapien. Donec rhoncus, enim sit amet sodales elementum, elit odio sagittis erat, at tincidunt leo neque non pede. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos hymenaeos. Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Mauris ac leo. Aliquam magna nibh, tincidunt ut, lobortis feugiat, consectetuer sed, sapien. Aenean dui eros, tempus non, pulvinar in, vestibulum sed, urna. Nullam eget arcu a pede adipiscing vestibulum. Donec accumsan lacus nec dolor. Etiam porttitor elit. Quisque suscipit, arcu id porttitor vehicula, sem eros congue nulla, id consequat massa diam at dui. Quisque quis massa. Suspendisse metus justo, pellentesque et, sagittis sit amet, consectetuer imperdiet, sapien. Nullam eu neque eget risus porttitor accumsan. Vivamus cursus pretium tortor.

Nulla pharetra dignissim enim. Nam cursus eros ut massa. Proin rutrum. Donec non urna non leo aliquam cursus. Vivamus ornare viverra lacus. Fusce id sapien. Donec rhoncus, enim sit amet sodales elementum, elit odio sagittis erat, at tincidunt leo neque non pede. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos hymenaeos. Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Mauris ac leo. Aliquam magna nibh, tincidunt ut, lobortis feugiat, consectetuer sed, sapien. Aenean dui eros, tempus non, pulvinar in, vestibulum sed, urna. Nullam eget arcu a pede adipiscing vestibulum. Donec accumsan lacus nec dolor. Etiam porttitor elit. Quisque suscipit, arcu id porttitor vehicula, sem eros congue nulla, id consequat massa diam at dui. Quisque quis massa. Suspendisse metus justo, pellentesque et, sagittis sit amet, consectetuer imperdiet, sapien. Nullam eu neque eget risus porttitor accumsan. Vivamus cursus pretium tortor.

-

More

Thank you very much.

We received your query. We will contact you soon.

-

More

Error.

Error in comminucation please fill form again. We are very sorry for that.